Ever wondered about the process behind making a glass bottle?

Discover the intricate steps involved in transforming raw materials into the everyday item we often take for granted. From sand to stunning vessel, delve into the fascinating journey of how glass bottles are meticulously crafted. Uncover the techniques, precision, and artistry required in the production of these common yet essential containers.

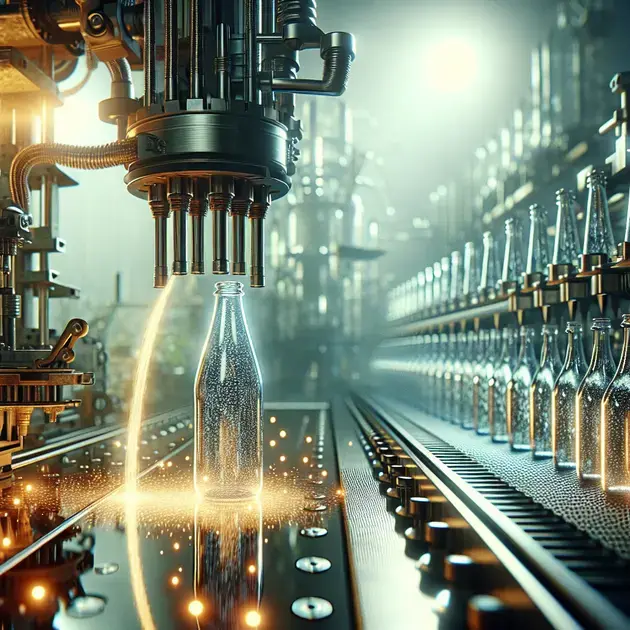

The Glass Bottle Manufacturing Process

When it comes to manufacturing glass bottles, the process is a fascinating blend of artistry and precision. To start, raw materials such as sand, soda ash, and limestone are mixed in specific proportions and melted in a furnace at high temperatures. Once melted, the glass is then shaped using molds or through a blowing process to achieve the desired bottle shape.

After the bottles are molded, they go through annealing, a process where the glass is slowly cooled to relieve any internal stresses and strengthen the bottles. Following annealing, the bottles undergo inspection for any defects or imperfections before moving on to labeling and packaging for distribution.

For a visual exploration of the glass bottle manufacturing process, websites like Glass Packaging Institute offer detailed insights and resources on how glass bottles are made, showcasing the intricate steps involved in creating these essential containers.

Understanding the manufacturing process behind glass bottles not only enhances our appreciation for this everyday item but also sheds light on the craftsmanship and meticulous techniques employed in producing them.

Overall, the glass bottle manufacturing process is a blend of science and art, showcasing the intricate steps involved in creating these essential containers that are integral to various industries worldwide.

Exploring the Art of Glass Bottle Production

Exploring the art of glass bottle production unveils a world of creativity and skill that goes into crafting these ubiquitous containers. Glassblowing, a traditional technique used in creating glass bottles, involves skilled artisans shaping molten glass into diverse forms using a blowpipe and various tools.

Modern advancements in glass manufacturing have introduced automated processes that enhance efficiency while maintaining the craftsmanship and quality of glass bottles. From custom designs to intricate patterns, the artistry behind glass bottle production allows for endless creative possibilities.

Websites like Glass Alliance Europe provide in-depth insights into the artistic aspects of glass bottle production, showcasing the innovative designs and techniques employed by glassmakers around the world. By exploring these resources, one can gain a deeper appreciation for the artistry and craftsmanship inherent in glass bottle production.

The art of glass bottle production not only serves functional purposes but also acts as a medium for artistic expression, blending aesthetics with functionality to create objects of beauty and utility.

Delving into the art of glass bottle production reveals a captivating world where tradition meets innovation, showcasing the timeless beauty and versatility of glass as a material for creating exquisite bottles.

Step-by-Step Guide to Creating Glass Bottles

Creating glass bottles involves a series of intricate steps that require precision and expertise to achieve the desired results. The first step is gathering the raw materials – sand, soda ash, and limestone – and mixing them in the right proportions to form glass.

Once the glass mixture is ready, it is melted in a furnace at high temperatures to create molten glass. The molten glass is then shaped either through blowing into molds or using automated machinery to achieve the desired bottle shape and design.

After shaping the bottles, they undergo annealing, where they are slowly cooled to strengthen the glass and reduce internal stresses. Quality control checks are conducted to ensure each bottle meets the required standards before proceeding to labeling and packaging.

Websites like Glass Packaging Institute offer detailed guides on the step-by-step process of creating glass bottles, providing insights into the various stages involved in manufacturing these essential containers. By following these guidelines, individuals can learn more about the intricacies of glass bottle production and the craftsmanship behind each bottle.

Mastering the step-by-step process of creating glass bottles requires a blend of technical expertise and artistic vision, highlighting the meticulous craftsmanship and attention to detail that goes into producing these versatile containers.

Crafting Unique Glass Bottle Designs

When it comes to crafting unique glass bottle designs, creativity and innovation are key. One approach to creating distinctive bottles is through the technique of embossing. By adding intricate patterns or designs to the surface of the glass, manufacturers can enhance the visual appeal of the bottles. This not only makes the bottle of glass stand out on the shelf but also provides a tactile experience for consumers.

Another method for crafting unique glass bottle designs is through the use of colored glass. By incorporating different hues into the glass composition, manufacturers can create bottles that are not only visually striking but also eco-friendly, as the color is often achieved through the use of natural minerals. This approach allows for endless possibilities in terms of customization and branding.

Furthermore, the shape of the bottle can also play a significant role in creating a unique design. By opting for unconventional shapes or incorporating intricate details such as handles or asymmetrical curves, manufacturers can elevate the aesthetic appeal of the bottle of glass, making it a standout piece in any collection.

Considering these various approaches to crafting unique glass bottle designs, it’s clear that the possibilities are endless. By experimenting with different techniques and materials, manufacturers can create bottles that not only serve their practical purpose but also double as works of art.

Tips for Eco-Friendly Glass Bottle Packaging

As consumer demand for sustainable packaging solutions continues to rise, incorporating eco-friendly practices into glass bottle packaging is essential. One effective tip for achieving this is to use recycled glass in the production of bottles. By utilizing post-consumer glass, manufacturers can significantly reduce the environmental impact of their packaging while still maintaining high-quality standards.

Additionally, opting for lightweight glass bottles can help minimize the carbon footprint associated with transportation and distribution. By using thinner glass walls without compromising durability, manufacturers can reduce the overall weight of the bottle of glass, leading to lower emissions during shipping.

Another tip for eco-friendly glass bottle packaging is to prioritize reusable or refillable designs. By offering bottles that can be refilled or repurposed, manufacturers can promote a circular economy and reduce single-use plastic waste. This approach not only benefits the environment but also resonates with consumers who are actively seeking sustainable product options.

Furthermore, embracing innovative packaging technologies, such as biodegradable labels or vegetable-based inks, can further enhance the eco-friendly profile of glass bottle packaging. By exploring these alternatives, manufacturers can position their products as environmentally conscious and appeal to conscientious consumers.

Innovations in Glass Bottle Production Technology

The glass bottle industry has seen significant advancements in production technology in recent years, paving the way for more efficient and sustainable manufacturing processes. One notable innovation is the adoption of lightweighting techniques, which involve optimizing the bottle design to reduce the amount of glass used while maintaining structural integrity. By employing advanced engineering simulations and material analysis, manufacturers can create lighter yet durable bottles of glass that are both cost-effective and eco-friendly.

Another key innovation in glass bottle production technology is the integration of automation and robotics in the manufacturing process. By streamlining production lines and reducing manual labor, manufacturers can enhance efficiency, accuracy, and consistency in bottle production. This not only increases output but also ensures a higher level of quality control throughout the manufacturing process.

Furthermore, the incorporation of recycled materials into the glass production process is a significant innovation in the industry. By reusing cullet, which is crushed waste glass, manufacturers can reduce the energy consumption and raw materials required for glass manufacturing. This closed-loop system promotes sustainability and reduces the environmental impact of producing bottles of glass.

Overall, with these innovations in glass bottle production technology, manufacturers can not only improve their operational efficiency but also contribute to a more sustainable and environmentally friendly industry. By embracing these advancements, the glass bottle sector is poised for continued growth and evolution in the years to come.

**

Conclusion

**

In exploring the intricate world of glass bottle manufacturing, it becomes evident that the process is a harmonious blend of art, science, and innovation. From the meticulous crafting of raw materials into molten glass to the shaping, annealing, and quality control stages, each step showcases the precision and expertise required to create these essential containers. The fusion of traditional glassblowing techniques with modern automated processes highlights the industry’s commitment to efficiency without compromising on quality craftsmanship.

Furthermore, diving into the realm of unique glass bottle designs reveals a realm of creativity and ingenuity where embossing, colored glass variations, and unconventional shapes converge to offer limitless possibilities for manufacturers to showcase their artistry. The emphasis on eco-friendly glass bottle packaging tips underscores the industry’s shift towards sustainability, with recycled materials and reusable designs paving the way for a greener future.

The innovations in glass bottle production technology signal a new era for the industry, with lightweighting techniques, automation, and the integration of recycled materials leading the charge towards efficiency and sustainability. By embracing these advancements, manufacturers can not only streamline their operations but also contribute to a more environmentally conscious sector poised for continuous growth and development.

In conclusion, the journey through the art, technology, and sustainability facets of glass bottle production unveils a dynamic landscape characterized by creativity, efficiency, and environmental responsibility. By delving into these elements, we gain a deeper appreciation for the meticulous craftsmanship and innovation that shape the glass bottle industry, paving the way for a more sustainable and visually captivating future in packaging design and production.